Building trust in manufacturing through connection technology.

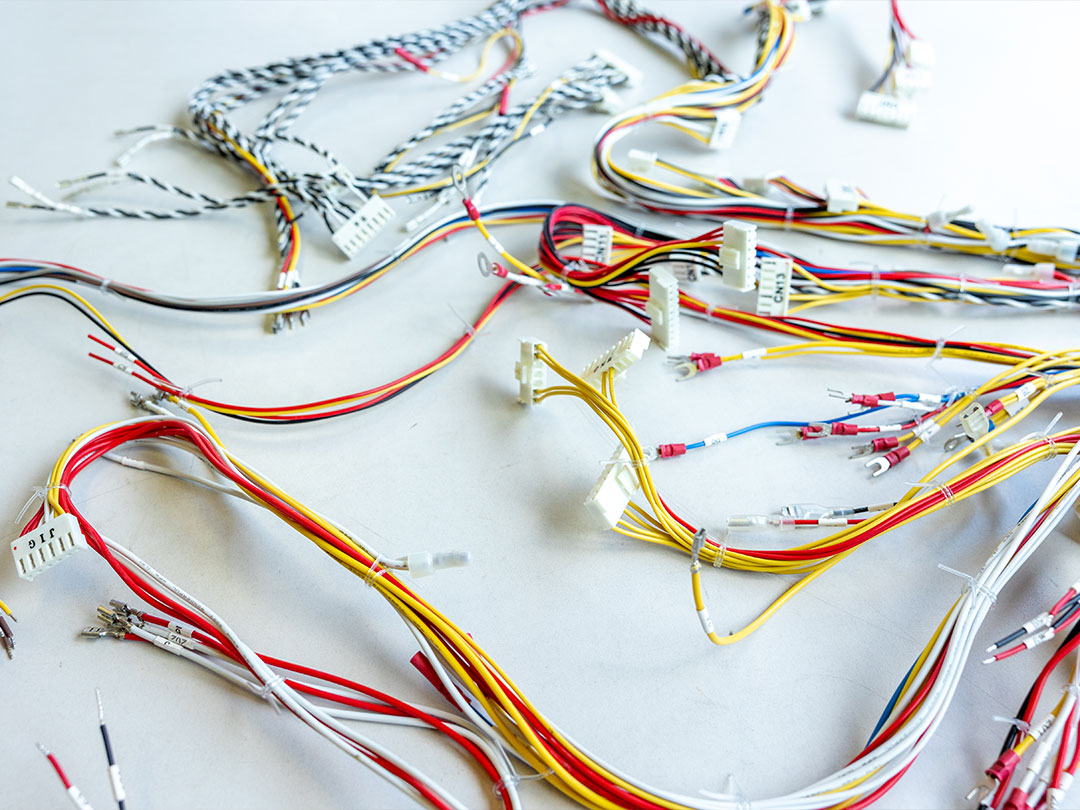

We manufacture approximately 1,543 models of wire harnesses each year, primarily for industrial electrical equipment.

By sharing information in real time between our in-house factory in Tamba and overseas production facilities, we ensure strict quality control, on-time delivery, and a stable supply.

For large-volume orders where cost efficiency is key, production is handled overseas, while small-lot orders requiring detailed customization are managed domestically — enabling us to maintain an optimal production system for every product.

Strengths Seiko Denki

-

55 Years of Excellence in High-Quality Manufacturing

- Since our founding in 1970, we have built a solid foundation of trust and achievement through long-standing partnerships with leading companies in the industrial and commercial equipment sectors.With the flexibility and responsiveness that large corporations often lack, we deliver consistently high-quality products backed by sincere craftsmanship and reliable service.

-

Flexible Production from Small Lots to Mass Manufacturing

- Through close coordination at our domestic facilities and real-time information sharing with our partner factory in Vietnam, we build the optimal production system for each project—from prototyping and small-lot production to full-scale mass production.

-

Custom Wire Harness Design to Meet Every Requirement

- We respond quickly to specification changes and additional requests based on each application and design requirement.

Our custom wire harnesses are designed to meet the needs of production sites that require multi-variety, small-lot, and individually tailored solutions.

-

Each Individual Plays a Leading Role in a Responsible Team Structure

- With a compact team of skilled professionals, we have built a structure founded on responsibility and strong collaboration.By preventing over-reliance on individuals, we strive to create an organization that remains stable and responsive, even in the absence of any one member.

Manufacturing Process Manufacturing Process

Cutting and Crimping

- ・Cutting

- In this process, wires and cables used in our products are cut to the specified lengths.

The outer insulation is also stripped to the designated length in preparation for terminal crimping onto the conductor.

The cutting process is mainly performed using casting machines and air strippers, which automatically and efficiently handle both cutting and stripping operations.

For special cables or materials that cannot be processed with these machines, we use hand tools and custom jigs to ensure precise, flexible handling.

- ・Crimping

- This process involves crimping terminals onto the conductor of the pre-cut wires.We primarily use semi-automatic and air-operated crimping machines to ensure precise terminal attachment.By changing the applicator — a component of the semi-automatic crimping machine used for pressing terminals — we can handle a wide variety of terminal types.Manual crimping using hand tools is also available when required.During the crimping process, the crimp height (the height of the terminal’s crimped section) is measured and recorded to ensure it remains within the specified range.

Processing

The processing stage includes Pressure welding, soldering, and assembly operations.

- ・Pressure welding

- This process involves using an IDC (Insulation Displacement Connection) machine to press flat cables into connectors.

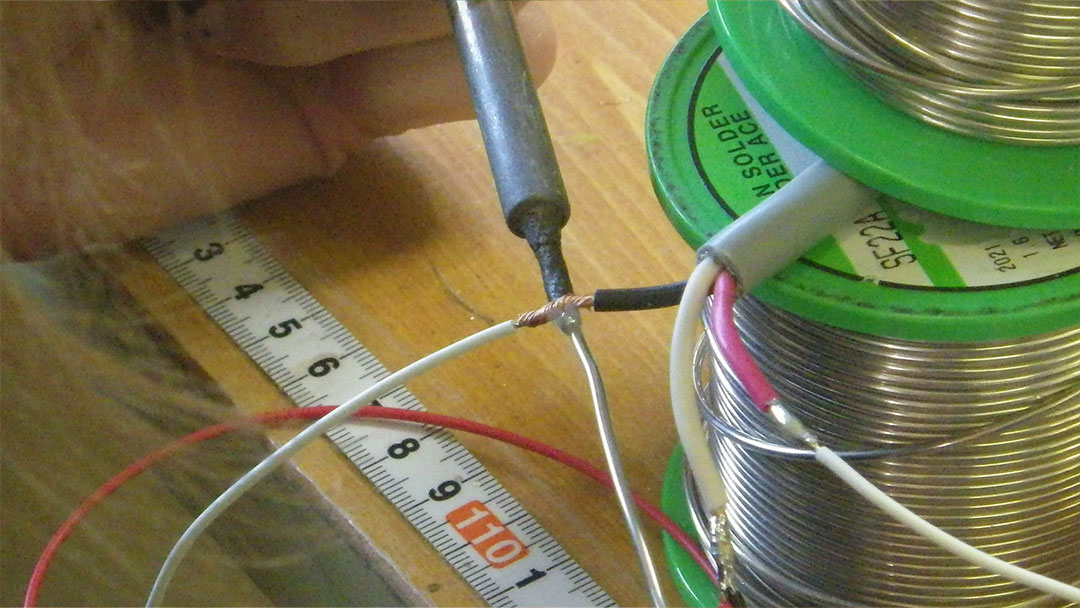

- ・Soldering

- This process involves soldering connections such as wires to connectors and wire-to-wire joints.Because this work requires a high level of technical skill, only personnel who have completed certified training and passed qualification tests conducted by our company are authorized to perform soldering operations.

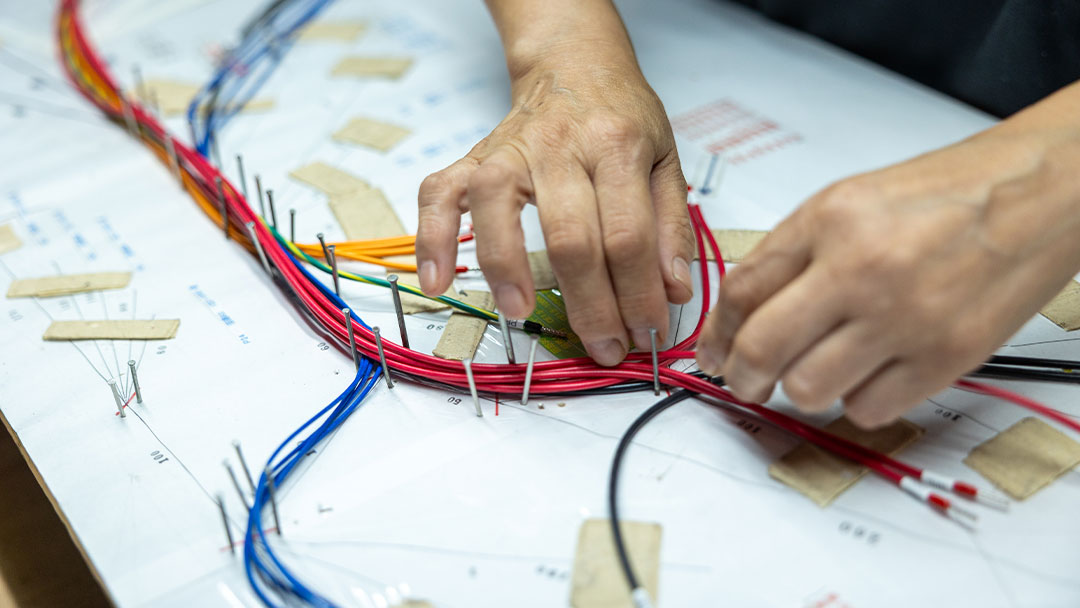

- ・Assembly

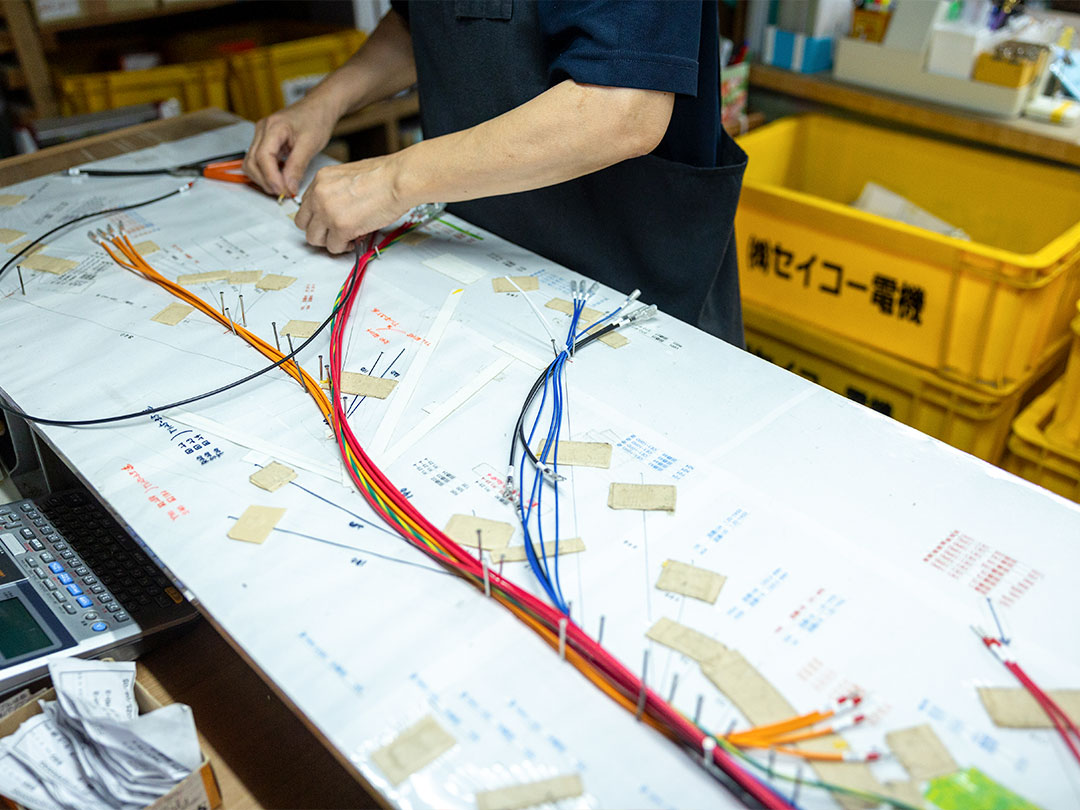

- After completing the previous processes, the components are assembled into finished products based on customer-provided drawings or full-scale wiring boards.Each wire is labeled with identification marks or mark tubes, then bundled and housed according to customer specifications to ensure precise and reliable assembly.

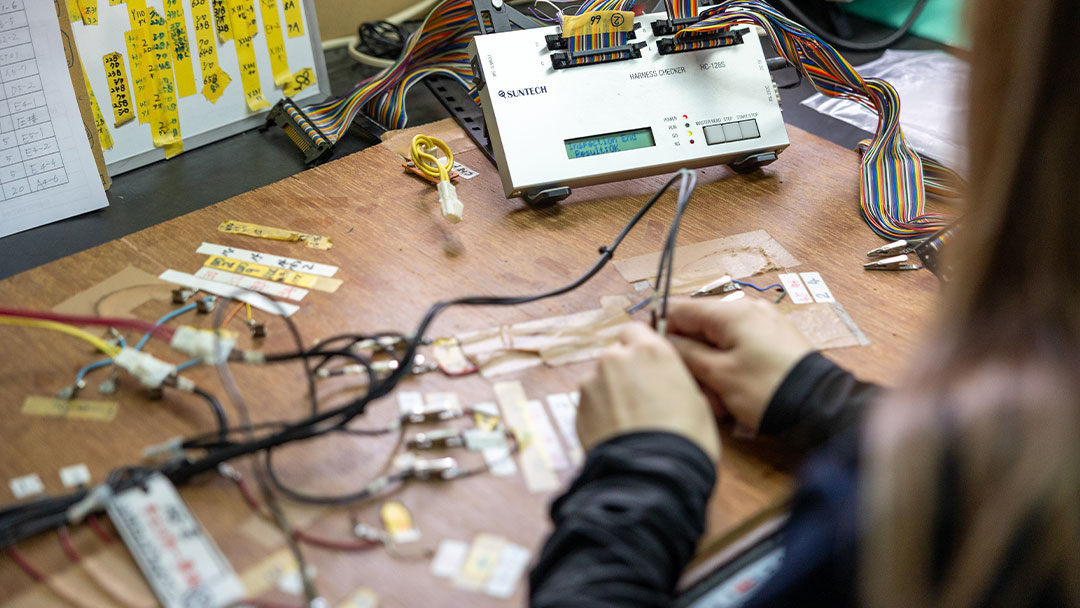

Inspection

The completed wire harnesses undergo a series of inspections to ensure quality and reliability.The main inspection items include visual inspection, continuity testing, and pin-pull testing.During the visual inspection, we check overall dimensions, crimping conditions, and bundling positions.Continuity testing is performed using testers and checkers to confirm there are no disconnections or wiring errors.In the pin-pull test, we verify that terminals are securely inserted into the connectors.

Shipping

After completing the inspection process, products move on to the shipping stage.Based on customer order forms and shipping lists, items are carefully picked and prepared for delivery.We take great care in packaging to ensure product safety and also provide attentive delivery service through our own transportation network.

Protecting Terminals According to Customer Needs

Use Cases Main Equipment in Use

-

Vending Machine

-

Touchscreen Ticket Vending Machine

-

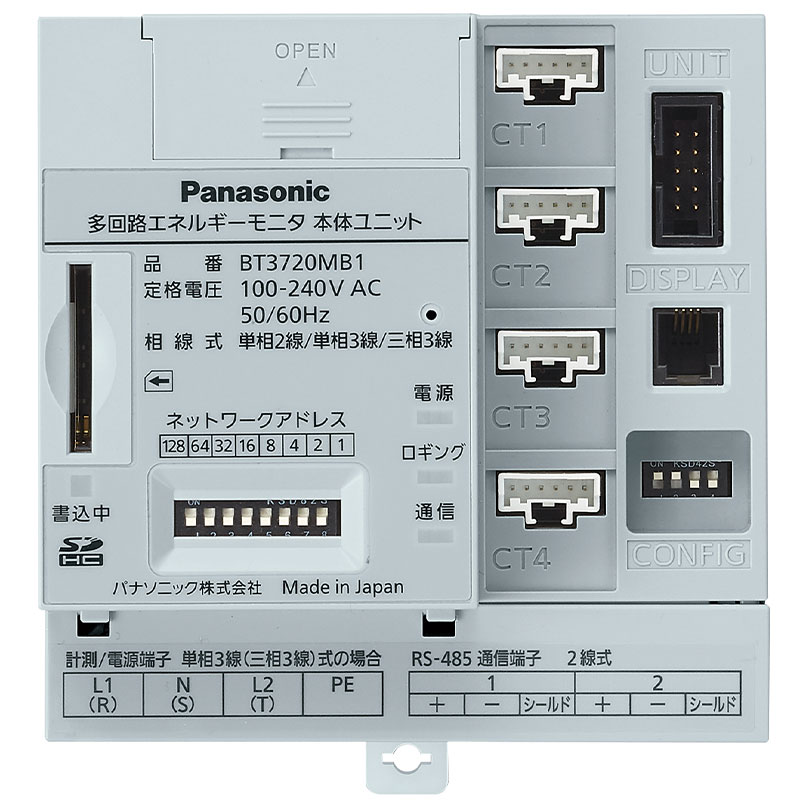

Energy Monitor

They are also used in environmental testing equipment, welding machines, and machine tools.

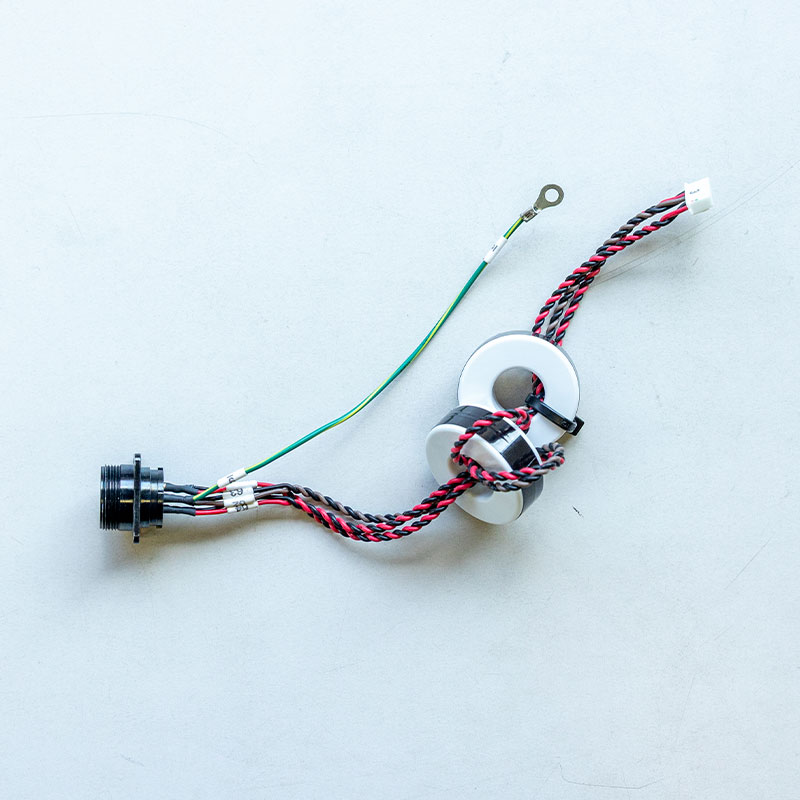

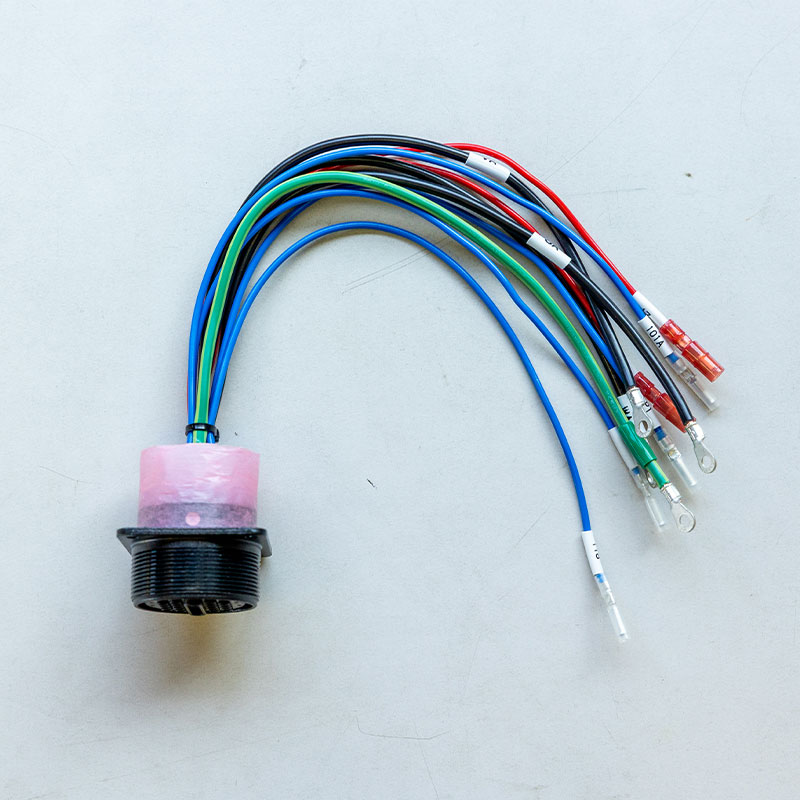

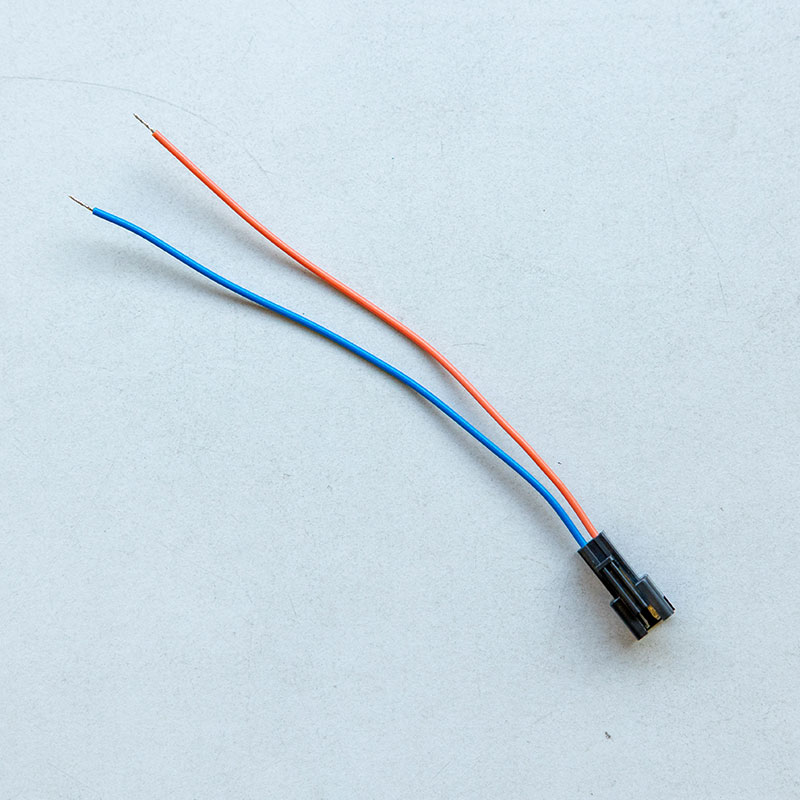

Product Product Introduction

Examples of Wire Harnesses We Manufacture

Business Partner Main Business Partners

ESPEC Corp.

Panasonic Switchgear Systems Co., Ltd.

SHIBAURA VENDING MACHINE CORPORATION